WSW bearing application knowledge: Application of rolling bearings in automobile

A car usually has about 30 kinds of 50 sets of bearings mounted in different parts of rotation. In practice, the automobile bearings are generally classified according to the installation or use parts. Corresponding to the automobile divided into engine, transmission system, steering system and air conditioning system, the automobile bearings can be first divided into engine bearings, transmission train bearings, steering system bearings and air conditioner bearings, and then further subdivided into the various parts of the above system and even the specific installation parts of the bearings. Due to the diversity of automobile and bearing designs, similar parts of different cars often adopt different component structures and bearing structures. The bearing installation part map and the corresponding bearing type spectrum table can indicate the installation part of the bearing in more detail and intuitively, and reveal the internal connection between the parts and the bearing by giving the bearing model, shape size and installation part at the same time.

Development profile

With the development of automobile technology, the design, manufacturing, test and application technology of automobile bearings have made great development. However, from the perspective of application, the development of automobile bearings can be summarized as the expanded application of general bearings, the development of special bearings and the improvement of bearing performance and life.

(1) Expanding application of general-purpose bearings

The improvement of automobile structure, the development of variety and specifications, performance and life, and the diversification of automobile design and bearing design lead to the expansion of the application scope of general bearings.

To date, general bearings in direct application in automobiles have covered almost all basic structural types of general bearings, more and more series and more and more specifications, while the improvement and development of general bearings in direct application have led to the generation of some new general bearing series and special bearings.

(2) Development of special bearings

On the basis of general purpose bearings, some automobile special purpose bearings have the structural and functional characteristics that the traditional rolling bearings do not have and are closely related to automobile applications. Among these automotive special bearings, the expansion of the structure and function of the hub bearings and the clutch release bearings is the most striking.

--Wheel bearing

1. The earliest hub bearing

The earliest hub bearings are composed of two sets of single column centripetal ball bearings or conical roller bearings. The disadvantage is that the installation and maintenance need to fill the grease and adjust the travel gap, and the grease type, improper dosage or insufficient cleaning and improper travel gap adjustment often bring serious consequences of greatly reducing the bearing life.

The improvement of the hub bearing composed of two sets of single-column bearings leads to the use of a sealed double-column bearing. The swimming gap of this bearing has been adjusted correctly when manufacturing, and the sealing and lubrication of the bearing itself can be exempted from dirt entry and grease type and dosage during installation. This hub bearing, which extends lubrication, sealing and gap adjustment functions, is known as the first generation hub bearing.

The outer ring of the first generation wheel hub bearing with a flange constitutes the second generation wheel hub bearing. Hub bearing this structure and function of the expansion of the supporting structure of the hub is greatly simplified, the amount of hub parts is reduced, and the installation has become simple and easy hub bearing structure and function further expanded the third generation hub bearing itself, short shaft and ordinary hub function, its inner ring flange to support the wheel and brake disc, the outer ring flange is used to connect the suspension. In addition to the technical advantages of simplifying the design of auto wheels and suspension devices, reducing volume, simplifying assembly, easy moving and minimal installation error, it also effectively reduces the cost of auto parts.

At present, the expansion of structure and function has made the hub bearings develop to the fourth generation of the constant speed universal joint, so that the technical performance and economic effect of the hub bearings have reached a new level.

The main role of the hub bearing (hub bearing) is to bear the weight and provide accurate guidance for the rotation of the hub, which bears both axial load and radial load, and is a very important component.

Traditional automotive wheel bearings are made of two sets of conical roller bearings or ball bearings, bearing installation, oil coating, sealing and swimming gap adjustment are made on the automobile production line. This structure makes it difficult to assemble, cost, and less reliable in the automobile production plant, and the bearings need to be cleaned, coated and adjusted when maintained at the repair point. Hub bearing unit is developed on the basis of standard Angle contact ball bearing and cone roller bearing, it will be two sets of bearings as one, with good assembly performance, can omit gap adjustment, light weight, compact structure, large load capacity, for sealed bearing can be loaded with grease, omitted external hub seal and free from maintenance, has been widely used in cars, also has gradually expanding application in trucks.

2. Installation and use of automobile wheel hub bearings

The most hub bearings in cars used to use single conpered rollers or ball bearings. With the development of technology, cars have been widely used in car wheel hub units. The range and usage of hub bearing units are growing, and now the third generation: the first generation is composed of two-column angular contact bearings. The second generation has a flange used to fix the bearing, which can be simply set the bearing to the wheel shaft with nuts. Make the car repair become easy. The third generation wheel hub bearing unit is equipped with the bearing unit and the anti-lock brake system ABS. Hub unit is designed to have internal flange and external flange, internal method? Bolt it to the drive shaft, and the outer flange fits the entire bearing together. Wear or damaged hub bearings or hub units can make your vehicle unsuitable and cost ineffective and even harmful to your safety.

3. Please pay attention to the following matters in the use and installation of hub bearings

1) For maximum security? Full and reliability, it is recommended that you always check the hub bearing, ——, take care of the early warning signals of wear: including friction noise during any turning or abnormal deceleration of the suspension combination wheel when turning.For rear wheel driven vehicles, the front hub bearing should be lubricated when the vehicle travels to 38000 km. When replacing the brake system, check the bearings and replace the oil seal.

2) If you hear the noise from the hub bearing part, first, it is important to find the location where the noise occurs. There are many moving parts that may produce noise, or some rotating parts are in contact with the non-rotating parts. If it is confirmed that the noise is in the bearing, the bearing may be damaged and needs to be replaced.

3) Because of the working conditions of the front wheels are similar, pair replacement is recommended even if only one bearing is broken.

4) Hub bearings are sensitive and require correct methods and appropriate tools in any case. The bearings and parts shall not be damaged during storage and installation. Some bearings require large pressure-in, so special tools are required. Be sure to refer to the car manufacturing instructions.

5) The bearing should be installed in a clean and tidy environment, small particles into the bearing will also shorten the service life of the bearing. It is very important to maintain a clean environment when replacing the bearings. Do not allow to hammer the bearing, pay attention to the bearing does not fall to the ground (or similar improper handling).The condition of the shaft and bearing housing should also be checked before installation, and even minor wear can lead to poor coordination and thus cause early failure of the bearing.

6) For the hub bearing unit, do not attempt to open the hub bearing or adjust the sealing ring of the hub unit, otherwise damaging the sealing ring will cause water or dust entry. Even the rollers of the seal and inner rings were damaged, causing a permanent failure of the bearings.

7) The sealing ring containing the ABS device bearing has a magnetic thrust ring that cannot be collided, impacted, or collided with any other magnetic field. Remove from the box before installation and keep them away from the magnetic field such as motor or power tools used etc. When installing these bearings, change the operation of the bearings by observing the ABS alarm pins on the dashboard.

8) A hub bearing is equipped with an ABS magnetic thrust ring. In order to determine which side of the thrust ring is installed, a light thing is used * near the edge of the bearing, and the magnetic force generated by the bearing will attract it. Install one side of the magnetic thrust ring inside, facing the sensitive elements of the ABS.

Note: Incorrect installation may cause the functional failure of the brake system.

9) Many bearings are sealed, and these bearings do not require grease throughout their life. Other unsealed bearings such as double-column tapered roller bearings must be lubricated during grease. Because the size of the bearing cavity is different, it is difficult to determine how much oil to add. The most important thing is to ensure that there is oil in the bearing. If the oil is too much oil, the excess oil will seep out when the bearing rotates. General experience: during installation, the total amount of grease is 50% of the bearing gap.

10) When installing the locking nut, the torque size varies greatly due to the different bearing type and the bearing housing.

4. Pay attention to maintenance

In the process of maintenance, some cars are often found to have large driving noise, check the tire without abnormal wear, and turn the wheel on the elevator without obvious abnormal ring. This phenomenon is often caused by the abnormal damage of the hub bearings, the so-called abnormal refers to the bearing damage caused by the installation reason. The front wheel bearing of the car is generally double column ball bearings, if the installation of bearings when using hammer percussion installation, or in the installation of the bearing into the bearing housing, will cause damage to one side of the bearing roller. Noise is generated when the vehicle is driving, and when the wheels are off the ground, no obvious noise is heard because there is a better side of the roller path. Proper installation operation is the key to the long life of the bearing.

--Clutch release bearing

1. Function of the clutch release bearing

The clutch release bearing is installed between the clutch and the transmission, and the release bearing housing is loose on the tubular extension of the first shaft bearing cover with the relief bearing shoulder always against the release fork and back to the last position to maintain a gap of about 3~4mm from the release lever end (release finger).

Because the clutch pressure plate, release lever and engine crankshaft synchronous operation, and the release fork can only move along the clutch output shaft axis, directly with the release fork to dial the release lever is obviously not good, through the release bearing can make the release lever rotating one side along the clutch output shaft axial movement, so as to ensure the clutch can be smooth, soft release, reduce wear, extend the service life of the clutch and the whole transmission system.

2. Clutch release bearing working condition

In the process of axial load, impact load and radial centrifugal force during high speed rotation, the torsion moment is formed because the reverse force of the thrust release lever is not on the same line. Clutch release bearing has poor working conditions, intermittent high speed rotation and withstand high speed friction, high temperature, poor lubrication conditions, no cooling conditions.

3. Clutch release bearing unit tolerance

1) Single internal diameter deviation of the bearing unit shall be specified in Table 3-2.2) Single diameter deviation of the contact circle △ D1S: ± 0.5mm.3) Single diameter deviation of connection groove △ D2S: upper limit: 0 mm and lower limit: -0.30 mm.4) Actual set deviation from the classification fork △ HS is: upper limit: 0 mm and lower limit: -0.30 mm.5) Without axial load, the actual fit width deviation of bearing unit is △ TOS: push bearing unit is ± 0.5 mm and pull bearing unit is ± 0.8mm.

4. Failure form of the clutch release bearing

The failure forms of clutch release bearing mainly include: separate bearing loose sleeve, scattered steel balls of bearing inner and outer rings, wave (concave and convex) wear of release bearing ball head, abnormal sound of release bearing, and release bearing stuck.

3. Other special bearings

Other special car bearings mainly include tensioner wheel bearing, water pump shaft bearings, some steering shaft bearings in the steering system and steering gear bearings and manual transmission, main bearings in the reducer.

Performance and life span improvement

Generally speaking, the improvement of automobile bearing performance and life has the reasonable selection and change of general bearings? And the structure and function of the expansion of the three main ways.

Reasonable selection of general-purpose bearings

The diversification of general bearing design provides a broad space for the selection of automobile bearings. Choosing the most suitable structural type, swimming gap, precision, size and performance from many general bearings is often the key to improve the performance and life of automobile bearings.

1. Improvement of general-purpose bearings

The improvement of the internal structure and materials of general bearings to meet the special environment and special requirements of automobile applications improves the performance and life of automobile bearings. These improvements include improvements to bearing structure parameters, roller path and rolling body profile, retention structure and materials, sealing structure and materials and grease to improve bearing capacity, eliminate or reduce stress concentration, reducing volume, reducing friction wear and improving high speed and high temperature performance.

2. Expansion of the structure and function of general bearings

Considering the bearings and their adjacent parts as a whole or system, the overall structural performance and life are optimized through the expansion of the structure and function of the general bearing. The thus developed special automobile bearings not only improve the performance and life of the bearing itself, but also improve the performance and life of auto parts or assembly including bearings, and can simplify the automobile design, assembly, maintenance and reduce the cost of auto parts. In the future, automobile bearings will continue to develop along the above main directions, so as to meet the development requirements of automobile design diversification and performance and life improvement.

--Automotive engine bearings

Automobile engine bearings generally refer to the bearings used in the automobile engine itself and its accessories: that is, the bearings used in the crank link mechanism, gas distribution mechanism, fuel system, lubrication system, cooling system and ignition system.This section introduces the generator bearing, water pump bearing, ventilator bearing, transmission belt tension wheel bearing and supercharger bearing that are commonly used in the above mechanism or system.

--Generator bearing

(1) Classification

There are two kinds of generators in the automobile ignition system and excitation DC generator and semiconductor rectifier generator.

Among them, the alternator shows a rapid development trend due to its strong power generation capacity, large speed range, compact structure, reliable operation and long service life.For generator bearings, adapting to this development means that the carrying capacity, limit speed, rotation accuracy, lubrication and sealing performance, and noise performance must be improved.

(2) Design and analysis

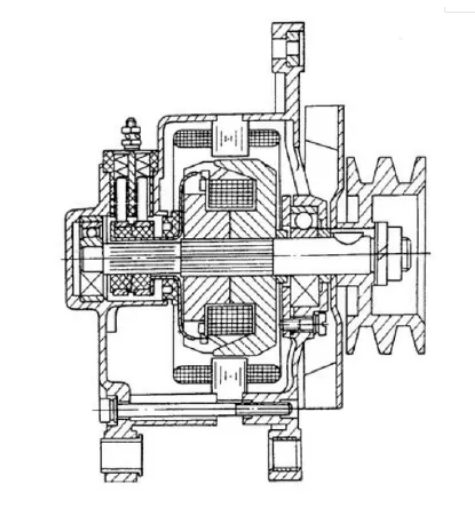

Use of generator bearings in semiconductor rectifier alternatator Fig:

Generator bearings are generally deep trench ball bearings and deep trench ball bearings with dust or sealing structure, the large force bearing wheel side sometimes also uses double column ball bearings, cylindrical roller bearings or other structural type bearings.The selection of generator bearing should be first considered the calculation life to meet the requirements, and then should be considered the limit speed, sealing, lubrication, noise and swimming gap problems.

1. Extreme speed

The limit speed listed in the bearing sample is the limit speed under standard conditions, which should be corrected according to the actual use conditions.When the correction value is lower than the use speed, select another bearing or conduct a high-speed design.

2. Seal

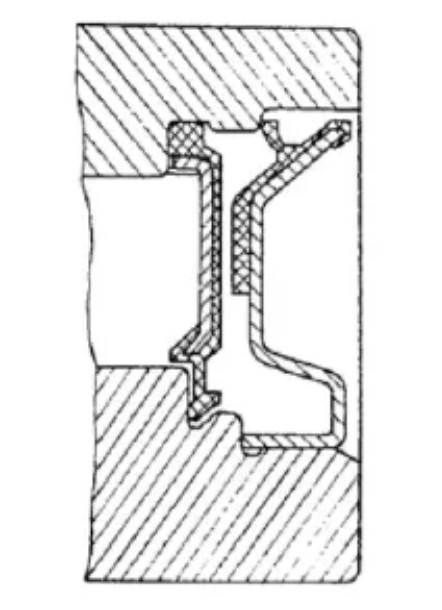

High speed and sealing are two contradictory characteristics of generator bearing seal design.Light contact high-speed rotary sealing ring has good torque, temperature rise, dust and fat sealing performance, but its mud resistance performance is poor; and sealing contact sealing ring will produce high temperature rise.Therefore, the seal design of the generator bearing must take into account the two contradictory characteristics of high speed and seal.In order to give consideration to the sealing and high speed, a good sealing design is to add an oil swing ring outside the light contact seal ring to form a maze seal to effectively prevent muddy water from entering the double sealing structure. The basic structure of this design is shown in the figure:

The outer sealing ring is composed of oil swing ring and light contact sealing lip, and forms a maze seal with the outer ring and inner seal ring. At high speed and low speed, the maze seal and light contact sealing lip prevent muddy water from entering, so as to achieve excellent sealing performance in the whole speed range from low speed to high speed.

3. Lubrication

The selection of engine bearing grease is generally considered in terms of high rotation speed, high temperature resistance, good low temperature starting performance and low noise.

The high-speed adaptability of the grease can be determined by the table by calculating the Ka Dm N value of the bearing.

Due to the need of low noise, the generator bearing grease can not be too thick, in order to improve the damping effect of the grease on the rolling body vibration, and to prevent the increase of noise and starting moment due to dry friction at low temperature.

Based on the above reasons and the consideration of high temperature resistance and waterproof performance, the lubrication of the generator bearing generally adopts composite calcium-based grease.

The filling amount of bearing grease can be determined according to the ratio of its grease lubrication limit speed and its actual operating speed.

---Ventilator bearing

(1) Function

In order to maintain the best operating temperature and reduce power consumption as much as possible, modern engines generally use adjustable ventilators. When the driving air flow and radiation dissipation are enough to ensure the optimal working temperature, the ventilator is stopped, and when the best working temperature is exceeded, the ventilator enters the working state.

This intermittent working ventilator has multiple transmission structures, while different structural ventilators have different requirements for bearings.But when installed directly in the ventilator impeller, the biggest problem with the bearings is a large load and possibly high temperatures of 150-230 degrees Celsius.

Therefore, in the automobile ventilator, the bearing must first consider the lubrication and sealing problems, and then ensure that the bearing outer ring and light metal shell even at high working temperature.Also, the bearing should be capable?The high torque load and accurate guidance produced by the imbalance of the ventilator, and the friction torque should be reduced as far as possible to facilitate energy saving and reduce noise.

(2) Design and analysis

The common ventilator uses silicon oil clutch or electromagnetic clutch to control the cooling fan work, and take the wind device using silicon oil clutch as an example to analyze the ventilator bearing. In a ventilator with a silicone oil clutch, the pump wheel of the clutch is driven by the engine, the turbine is firmly connected to the fan, and the bearings are mounted between the pump shaft and the turbine housing. The pump wheel transmits torque to the turbine through silicon oil, and controls the entry and exit of the pump wheel and silicon oil in the turbine working chamber by the bimetal temperature sensor directly mounted at the rear of the radiator, and adjusts the fan speed automatically according to the engine temperature to control the engine temperature.

---1. Deep groove ball bearing

Deep groove ball bearing is the most common type of rolling bearing. The deep groove ball bearing of this type consists of an outer ring, an inner ring, a set of steel balls and a set of holders. There are two types of deep groove ball bearing: single row and double row, deep groove ball structure is also divided into sealing and open structure, open type refers to the bearing without sealing structure, sealing type deep groove ball is divided into dust seal and oil seal. Dust seal cover material is steel plate stamping, which only plays a simple role to prevent dust from entering the bearing roller. The oil-proof type is the contact oil seal, which can effectively prevent the grease overflow in the bearing.

Single column furrow bearing type code is 6, and double column furrow bearing code is 4. Its structure is simple, easy to use, is the most common production, the most widely used class of bearings.

2. Double Row Bearing

Heavier ventilators require wider support housings and corresponding double-row angular contact ball bearings or pair-installed deep groove ball bearings. A sedan hood ventilator support structure mounted with two sets of deep groove ball bearings.

3. Roller Bearings

If there is enough space, the entire ventilator assembly can be supported with two deep groove ball bearings and a turbine and fan on the pump shaft. The ventilator assembly is positioned by two sets of grease-sealed deep groove ball bearings-swimming support. Only a set of ram outer coil roller bearings directly installed in the ventilator is under high temperature, so the lubrication, sealing and coordination of roller bearings must be designed accordingly.

--Tensioner wheel bearing

(1) Concept

With the widespread application of high camshaft and overhead camshaft in modern automobile engines, the synchronous chain drive and gear drive of camshaft have been gradually replaced by tooth belt drive.At the same time, the transmission of the automobile diesel engine fuel injection pump also uses a synchronous tooth belt.In order to facilitate the installation and adjustment of the synchronous tooth belt, the tension wheel is generally used on the loose edge of the tooth belt.In the more complex tooth belt drive, the inertia wheel is often used at the tight edge of the tooth belt to increase the package Angle of the drive wheel or change the position of the tooth belt.

(2) Design and analysis

1. Tensioner wheel for housing plate installation

The tensioning wheel with the housing plate has two typical designs, fixed by the housing plate by a bolt; by the swing tensioning band of the housing plate, but by the bolts passing through the inner hole of the bearing.The rolling bearings used in the above two designs are double-column concentric sealed ball bearings.Single-column concentric sealing ball bearings are often used in the tensioning wheels.

2. Eccentric tension wheel

The eccentric tension wheel is tightened by swinging around the eccentric hole in the underwriting, which is fixed by a double stud through the eccentric hole and a nut.

3. Light-weight design

The most notable development of the above tensioning wheel is the so-called lightweight design.The development of lightweight design greatly reduces the quality of tension wheel, and also effectively reduces the manufacturing cost of tension wheel.

4. Compact wheel action

The function of the tightening wheel is used to adjust the tightness of the timing belt, maintain the tension of the belt, avoid belt skid, and compensate for the elongation caused by belt wear and aging.Adjust and compensate for the deviation from the center distance of the engine system due to the machining errors of the shaft and the positioning hole.To some extent, you can eliminate the abnormal noise in the engine group operation caused by the belt elongation or swing.Inhibit the vibration of the transmission system.

5. Working principle of the tension wheel

When the engine system is unloaded, the belt where the tightening wheel is tightened, the rotation of the belt occurs during the belt axis. When the belt shaft is loaded, the belt of the belt wheel and stores the kinetic energy of the belt system into the elastic energy of the torsion spring for use during unloading.In order to maintain the proper tension force of the belt, compensate the belt wear and the elongation caused by aging, a certain torque is required.When the belt tightening wheel operates, the moving belt may arouse vibration in the tightening wheel, resulting in premature wear of the belt and tightening wheel.To this end, add a resistance mechanism to the tightening wheel.However, due to many parameters affecting the torque and resistance of the tightening wheel, and the influence of the parameters is different, so the relationship between the torque and resistance of the tightening wheel is very complicated.Torque change directly affects the change of resistance, and it is the main influencing factor of resistance. The main factor affecting torque is the parameter of torsion spring.Reducing the middle diameter of the torsion spring appropriately can increase the resistance value of the tightening wheel.

---Bearing unit

Base rolling bearing is a combination of grease sealed rolling bearing and various shapes of bearing housing.Base rolling bearing can be directly installed on the main body of the mechanical device through several bolts, with automatic centering performance, can supplement grease, etc., is a very easy to install and use products.

The housing rolling bearing consists of a ball bearing with a spherical outer diameter assembly and a bearing housing with a spherical inner hole.

Characteristics of bearing unit :

1) With the automatic centering function

The outer diameter of the outer spherical surface bearing and the inner diameter of the bearing housing match with the spherical surface, with the automatic centering function between the two, which can compensate for the inconsistent axis caused by the installation error and the deformation of the installation bottom surface.

2) Large load capacity

Because the inner structure of the outer spherical ball bearing is the same as the 6200 and 6300 series deep trench ball bearings, the IB belt housing outer spherical ball bearing can not only withstand the radial load, but?Can withstand a large axial load.At the same time, the bearing working noise is small.

3) Long service life

Outer spherical ball bearings are usually used in harsh working conditions such as dirt, dust, moisture and high temperature. The grease inside the bearing will deteriorate in a short time.Therefore, it is necessary to re-lubricate the outer spherical ball bearing within appropriate time intervals and replace the deteriorated grease with fresh grease.IB with cast iron outer spherical ball bearings with oil nozzle, can be re-lubricated, to ensure the perfect performance and long service life in any working environment.

4) Excellent sealing performance

Outer spherical ball bearing sides are sealed with heat-resistant and oil-proof rubber sealing ring and steel sheet dust cover.The dust cover assembly rotating with the inner ring can effectively prevent the external foreign body from entering the bearing and protect the bearing against the external pressure. This combined seal can prevent the soil, dust, and moisture into the bearing, and prevent the grease leakage inside the bearing.So that the bearing can also maintain the perfect working performance in a harsh working environment.

5) Strong bearing housing

Cast iron housing is the whole housing structure, the bearing housing is very rigid, to prevent the deformation of the bearing when assembly, the bearing housing is durable under any working conditions.

6) The bearing can be easily locked on the shaft

There are three ways to lock the shaft, the common method is to lock the inner ring elongation end of two tightening screws, can also use tight sleeve or eccentric sleeve lock.All three methods can easily lock the bearings on the shaft.

7) Special heat treatment for the bearing inner ring

The inner ring channel and its surrounding parts and after normal quenching, and the elongation end of the inner ring of the tight screw is repaired through high temperature local tempering to maintain toughness and impact resistance.After the local tempering around the inner ring screw hole, the bearing obtains better performance to prevent the screw from loosening during the bearing operation, and the screw is very tight will not cause the inner ring to burst.

8) Unique design to prevent outer ring rotation

The bearing outer ring is equipped with a unique stop pin (ball), which allows the bearing to automatically adjust, and prevents the outer ring from rotating, making the service life of the bearing longer.

9) The bearing and the bearing housing are fully interchangeable

Bearing and bearing housing are precision processed, bearing and bearing housing can be completely interchangeable, the bearing can be easily replaced at any time.

10) Easy to install

Outer spherical ball bearing has been injected with sufficient high quality grease to install the housing outer spherical ball bearing directly on the shaft.Therefore, harmful substances can not enter the bearing interior during the installation of the bearing unit.

Learn more about Bearing-Asia bearings, please click WSW Bearings to check the details.

Any questions or concerns, please click contact WSW Bearing to let us know.